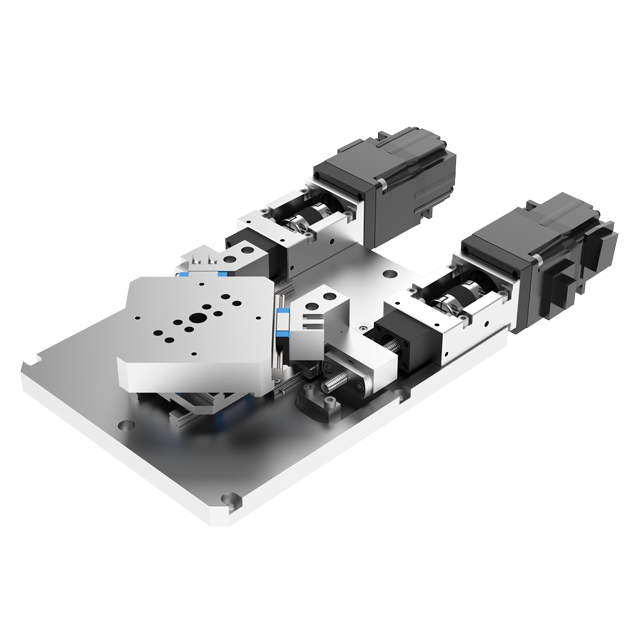

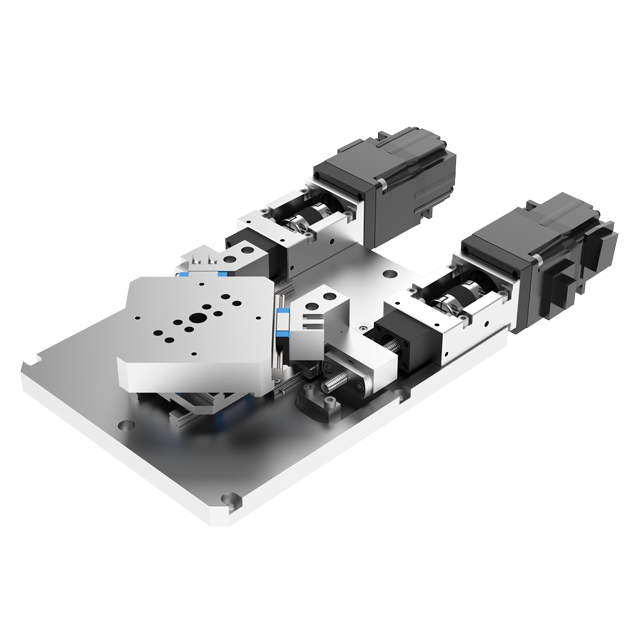

Cleanroom Precision Positioning Table TC

IKO Cleanroom Precision Positioining Table TC・・・E is the most suitable positioning table for use in a Cleanroom environment such as semiconductor or LCD manufacturing equipment or similar applications. The driving components and moving components inside of the table are sealed tightly with a stainless sheet and side covers, which prevent dust generated from within the table from being released to the surrounding environment.

Cleanliness of ISO Class 3 (Federal Standard 209D Class 1) can be achieved by IKO Cleanroom Precision Positioning Table TC with the original tight-sealing structure.

Product Features

IKO Cleanroom Precision Positioining Table TC・・・E is a light-weight, low-cross section, and compact precision positioning table, which is based off of the TE table but with a tight-sealing structure made possible by a stainless sheet and side covers. The ability to achieve low dust generation from the table to the surrounding cleanroom environment can achieve cleanliness of ISO Class 3 (Federal Standard 209D Class 1).

A precision ball screw adopted for the driving mechanism enables high precision positioning. Moreover, with regards to lubrication, IKO's C-Lube technology is integrated into the slide table and ball screw to provide maintenance-free operation.

1.Cleanliness level equivalent to ISO class 3 (Federal Standard 209D class 1)

| Sealing with a stainless sheet and side covers prevents dust generated by the table from escaping to the surroundings. Per cleanliness evaluation by IKO's measuring method, ISO class 3 (Federal Standard 209D class 1) has been achieved. |

Measuring condition

| Item | Condition |

|---|---|

| Measuring device | Particle counter |

| Air velocity in measuring zone | 2.5m/s |

| Measuring air amount | 28.3L(1cf) |

| Measuring time | 48 hours (10 min./time, 1 time/hour) |

Schematic diagram of the test equipment

TC60E300 (Lead of ball screw:10mm)

TC86E940 (Lead of ball screw:20mm)

2.Light-Weight, Low-Cross Section, and Compact

Light-weight and compact positioning table using high-strength aluminum alloy for its main components.

Low cross-section (54mm high for TC60E and 67mm high for TC86E) is possible due to optimum design of linear guides and ball screws.

It is a light-weight and compact positioning table using high-strength aluminum alloy for its main components. Moreover, the structure of various sensors are able to be installed using the groove on the side covers, which contributes to miniaturization.

3.High positioning accuracy

Higher precision positioning is achieved due to a combination of IKO's unique linear motion rolling guide technology and precision-ground ball screws.

4.High corrosion resistance

The main components are made from high strength aluminum alloy coated with alumite treatment or stainless steel sheet metal, which are excellent in terms of corrosion resistance.

5.Long-Term Maintenance free

Long-term maintenance free operation due to IKO unique C-Lube lubrication part built in the linear motion rolling guide and the ball screw.

This can reduce labor time for lubrication and increase the reliability of the equipment.

Some products are not shown in the catalogue. Also, modifications can be made to meet your requirements. Please do not hesitate to make inquiries.